Established In

The Year 2004

FAUE was established in the year 2004 as one of the pioneer Material Handling Equipment (MHE) Company with direct response to growing material handling equipments demands in Malaysia. Rapidly responding to the MHE needs, the large portfolio of equipments sourcing enables Faurtat Engineering to cover a wide range of markets in diverse sectors mainly in warehousing, manufacturing and logistics which also offer the broad range of capabilities includes Material Handling Equipment, Storage and Racking System, Lifting and etc.

Material Handling Equipment (MHE) Company with direct response to growing material handling equipments demands in Malaysia.

Stacker

Stacker is used to maximize operator productivity and performance when accessing and storing material.

Access

Equipments

Access equipment is used for gaining access to elevated or sunken positions. It is also used for raising or lowering plant or materials to a work area.

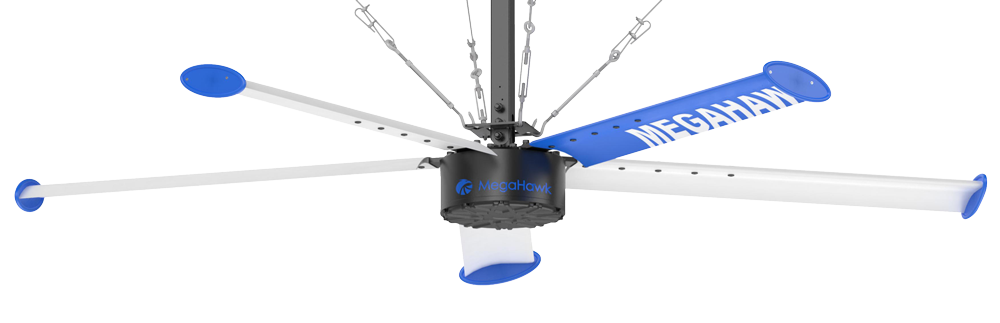

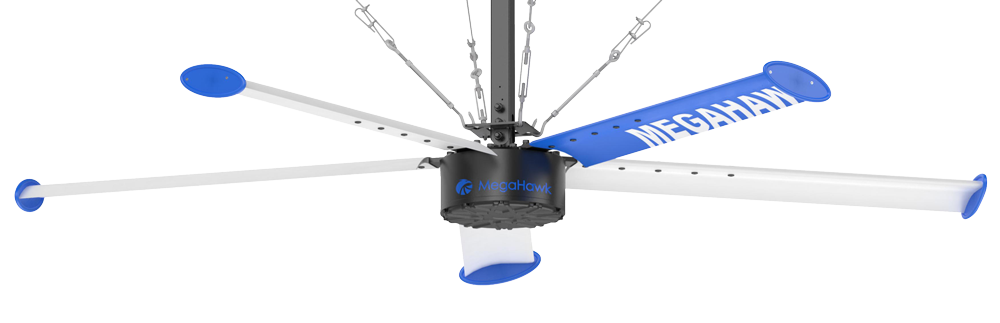

HVLS Fans

Without HVLS industrial fans, spaces can have uneven temperatures, with warm air accumating on top of ceiling and cold air accumating on to the ground, it leading to wasted energy and bill due to poor air circulation.

Material Handling Equipment, Storage and Racking System, Lifting

What are the differences between a pallet truck and a pallet lifter?

The main difference between a pallet truck and a pallet lifter is the level of automation and the lifting capacity. A pallet truck is typically manual or electric-powered and is used for short distances and lighter loads, while a pallet lifter is powered and can lift heavier loads to greater heights, often with the operator standing on a platform to control the lift.

How do I maintain my pallet truck or pallet lifter?

Regular maintenance is important to ensure that your pallet truck or pallet lifter continues to operate effectively and safely. Maintenance tasks may include checking and adjusting the brakes, lubricating moving parts, checking the hydraulic system for leaks, and inspecting the wheels and tires for wear. It is important to follow the manufacturer’s recommended maintenance schedule and to address any issues promptly to avoid more costly repairs down the line.

Is it safe to operate pallet trucks and pallet lifters?

Pallet trucks and pallet lifters are generally safe to use when operated correctly and with appropriate training and safety precautions. However, it is important to follow proper safety procedures, such as wearing appropriate personal protective equipment, ensuring that the equipment is properly maintained, and following proper loading and unloading procedures. It is also important to ensure that workers are trained on how to safely operate and interact with the equipment.

Our Customers

Explore a comprehensive range of top-tier warehouse equipment Malaysia and lifting equipment Malaysia, meticulously designed to enhance operational efficiency. Our selection encompasses robust pallet racking systems, versatile shelving units, and cutting-edge lifting equipment Malaysia such as forklifts and hoists. Committed to excellence, we prioritize quality, durability, and innovation, sourcing products from reputable manufacturers to meet and exceed industry standards. Backed by a team of experts, we provide personalized assistance to ensure you choose the ideal equipment for your specific needs. Beyond the initial purchase, our commitment extends to comprehensive support and maintenance services, ensuring the longevity and peak performance of your chosen equipment. Elevate your material handling processes with our reliable and advanced solutions, tailored for the dynamic demands of the Malaysian market.

Material handling equipment Malaysia refers to a diverse range of tools and machinery utilized for the efficient movement, storage, control, and protection of goods within various industrial settings. In Malaysia, the market for material handling equipment has witnessed substantial growth, driven by the country’s expanding manufacturing and logistics sectors. These material handling equipment Malaysia types include conveyor systems, forklifts, pallet jacks, and automated solutions, contributing to streamlined operations and increased productivity across industries. A lift truck Malaysia, commonly known as a forklift, is a specialized industrial vehicle designed for lifting, transporting, and stacking materials. Lift Truck Malaysia play a pivotal role in various sectors, including manufacturing, warehousing, and logistics, contributing to the seamless movement of goods within facilities.

Material handling equipment Malaysia enhances efficiency by facilitating the swift and organized movement of goods, reducing manual labour, and minimizing the risk of damage during transportation and storage.

Yes, Malaysia has established safety standards for material handling equipment Malaysia to ensure workplace safety. Compliance with these regulations is crucial for businesses utilizing such equipment.

Lift trucks Malaysia enhances operational efficiency by expediting the loading and unloading of materials, optimizing storage space, and reducing manual labour, ultimately leading to increased productivity.

Yes, there are training and certification requirements for lift truck operators in Malaysia. It is essential for operators to undergo proper training to ensure safe and proficient handling of the equipment.